Your shopping cart is empty!

Welcome visitor you can login or create an account.

EXPERTS in tungsten carbide hardfacing & wear prevention

Inquire about our INITIAL MINE ASSESSMENT

If you would like to learn more about our mine inspection or have any enquries about our products, please call Tim on 07 3277 9630 or fill out the form below.

*

Name

*

Email

Phone

*

Enquiry

*

Captcha

BackWear Life Trials

On this page we compare ARM hardfacing solutions with other options.

To confirm the efficiency, durability and cost effectiveness of our wear parts (often patented), we are always prepared to participate in (managed) wear life trials against competitors products.

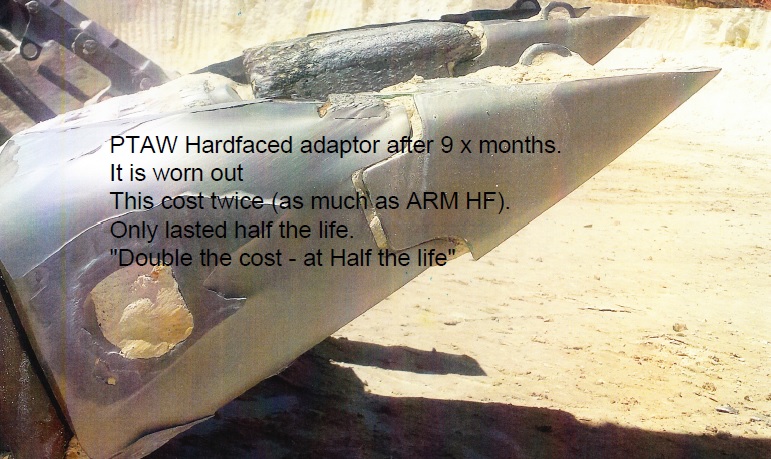

ARM Hardfacing Vs Plasma Transfer Arc Welding (PTAW)

| ARM HF adaptor trial after 9 x months (4000 hours) - hardly worn. (Note - this product is patented in Australia) |

| ARM HF vs PTAW adaptor trial - after 9 x months (4000 hours) PTAW is totally worn out. Note - this is the same bucket and mine that the ARM HF adaptor was working in. |

| ARM HF adaptor trial - this is the standard ESCO 110 series option - worn out after 9 x months (4000 hours) |

| This PTAW hardfaced dragline bucket adaptor has only lasted for 2 weeks. ARM HF options last 6 months on this mine site and can then be rebuilt for 50% of new cost. |